Our sites

eServices

- Grenoble Savoie Directory

- Reserved Services

- Intranet Grenoble INP

Connexion

Connexion

Connexion

Connexion

What is CEMAM ?

The Centre of Excellence of Multifunctional Architectured Materials (CEMAM) is devoted to the design, creation, and the fundamental understanding of new multifunctional materials and improved performances that will underlie the technologies of the future. This centre is managed by Professor Yves Bréchet. Based in Grenoble, it represents 130 permanent researchers in materials science, chemistry, mechanics, and biology. CEMAM also promotes close collaborations with industry and other universities.

Context & Topic

Architectured materials are, according to the definition given by Ashby, combinations of two or more materials, or of materials and space, assembled in such a way as to achieve properties (e.g. toughness, work hardening capacity, ductility, electrical or thermal conductivity) not offered by a monolithic material. Exploring the potential of architectured materials requires to emphasize the choice of components, their relative volume fraction, their 3D arrangement as well as the way they are connected to each other. Most of the architectured materials investigated in the literature have been cellular structures, i.e. combining material and space.

Architectured microstructures would suggest that one can control in 3D the spatial arrangement of various microstructures. Being able to produce architectured microstructure could be of interest to achieve novel properties that would be impossible to obtain using only one microstructure.

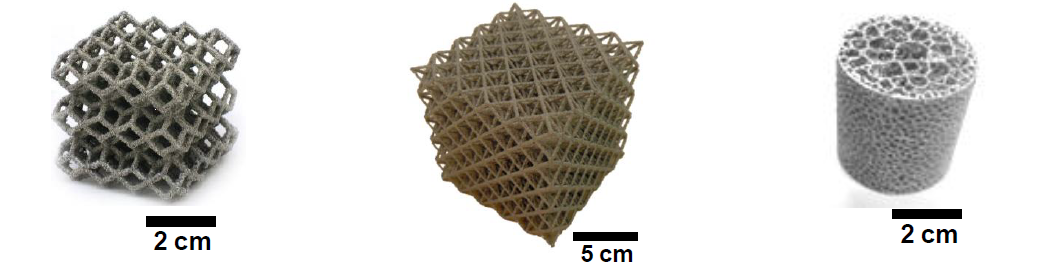

The aim of this post-doc is to explore an innovative route to achieve Titanium

architectured microstructures exhibiting a well-controlled 3D arrangement of the different constituents by combining two existing processes: Electron Beam Melting (EBM) and Spark Plasma Sintering (SPS). Additive Manufacturing (AM) technologies have revolutionized the production of Ti-alloys parts (e.g.) making possible the production of parts with a high degree of freedom in design, see Erreur ! Source du renvoi introuvable.. In addition, SPS enables to consolidate easily and quickly metallic materials, limitating microstructural evolution such as grain growth, see e.g. for Ti-alloy. EBM is used to perfectly control the 3D spatial distribution of the first constituent of the architectured microstructure, typically following the frame of a lattice

structure. SPS is then used to fill in the remaining space.

Figure 1. Examples of lattices structures fabricated by Electron Beam Melting at CEMAM.

Post-Doctoral Position Program

The first stage of this two years project will consist in producing Ti-6Al-4V cellular structures by EBM. Different geometries will be fabricated and densities will be varied. Those structures could be heat treated so as to modify the microstructure within the lattice. During the second stage of the project, the lattice structures will be filled with Ti powders (different alloys can be used here) before being flash sintered. The thermomechanical paths during the sintering operations will have to be optimized to produce fully dense specimens. Finally the architectured microstructures generated will be characterized and the mechanical properties will be evaluated and compare to monolithic materials.

Collaborations

This project will be supervised by Guilhem MARTIN from Grenoble and Damien FABREGUE from Lyon . The post-doctoral fellow will be settled in Grenoble but regular trip to Lyon are planned. Lyon is just one hour drive from Grenoble. Regular discussions with Professor Yves Bréchet are also planned.

Post-Doctoral Profile

The candidate must have a PhD degree in Materials Science. The post-doctoral fellow has developed skills in structural characterization using techniques such as SEM, EBSD, or X-ray tomography. A solid background in physical metallurgy and structure-properties relationships is required. An experience in the field of additive manufacturing would be interesting. The candidate will have to take initiative to develop new experimental procedures and carefully discuss the results. To be able to work as a team is crucial for this project.

Contacts

People interested are encouraged to contact either Guilhem MARTIN either Damien FABREGUE by email, see below.

email: guilhem.martin@simap.grenoble-inp.fr

Tel: +33 (0)4 76 82 63 42

Laboratoire SIMaP/Equipe GPM2

Domaine universitaire

101, rue de la physique

38402 Saint Martin D'Hères

email: damien.fabregue@insa-lyon.fr

Tel: +33 (0)4 72 43 81 79

Laboratoire MATEIS/ Equipe Métal

INSA Lyon - Bâtiment Saint Exupéry

25, Avenue Jean Capelle

69621 Villeurbanne

mise à jour le 3 mai 2016